What are elastomeric wall coatings (EWC)?

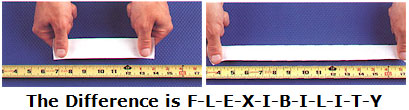

Elastomeric wall coatings are designed for exterior masonry surfaces like concrete, stucco and concrete block. They are generally acrylic latex masonry paints designed to be applied in very thick films (about 10 times as thick as regular paints); they are tough and flexible, and stretch as cracks underneath open and close, thus bridging the cracks and keeping wind driven rain out while maintaining a nice appearance. These coatings are called EWCs for short. They can be tinted to a light color. The EWC should be applied after cracks more than 1/16" are caulked with a quality acrylic ( e.g. Multiflex AC) or siliconized (not SILICONE) caulk. (If the stucco is particularly porous, a masonry primer or paintable sealer should be applied first. Use Ultraprime, (a special primer for EWCs) Applications of the EWC RainShield is usually at about 13-15 square feet/kg, and two coats should be applied.

We are building a house at Lonavala, near Mumbai, which has heavy shower during the monsoon. I am interested in finding out whether or not we should spend the extra money on using an "elastomeric" paint, as opposed to any other paint that would offer us the same effect but not be as costly.

Normally paints will not give same effect as you get with a properly applied elastomeric wall coating. Elastomeric wall coatings are exterior acrylic latex masonry paints designed to be applied in very thick films (about 10 times as thick as regular paints); they are tough and flexible, and stretch as cracks underneath open and close, thus bridging the cracks and keeping water out while maintaining a nice appearance. These coatings are called EWCs for short. They can be tinted to a light color.

The EWC should be applied after cracks more than 1/16" are caulked. Applications are usually at about 13 - 15 square feet/kg, and two coats should be applied. The crack bridging capability is related to film thickness. The thickness is of course much greater than with a conventional paint and this leads to significantly higher initial cost vs. with regular paint. It is also important that water is not allowed behind the EWC, so all caulking must be in good shape, chimneys must have rain caps, wall tops must be water proof, etc. EWCs are not be applied to surfaces where water normally gets behind them, like retaining walls.

Apart from protection from water, EWCs also keep heat out of building, which makes inside room cool.

I wanted to buy elastomeric in deep red colour, but have been told that product is not available in dark colours. What is the reason and any other alternative?

EWCs are manufactured to get high elongation and good dirt resistance, elastomeric wall coatings may "chalk," particularly in sunny exposures, to the point where dark colors may lighten more than surrounding trim painted with conventional paints. Hence dark colours are not offered in elastomerics. A more colourant will lead to cost increase. A better approach is to apply two coats of normal paints such as Reflection ( Refer www.walruspaints.com for more details) in desired colours over elastomeric coatings.

I have a stucco finish wall that was built around a pool area. Originally painted with oil base. Can latex or elastomeric be used over this. Which is preferable? Delhi weather ranges from some days in 0 oC to some days in 50 oC. Wall has some minimal cracking.

You may use an elastomeric coating, but the main question is, will water access the stucco from behind… if so, it will lift the coating and cause potentially serious blistering. This can happen if the wall is a retaining wall with earth behind it, or there is any way water can otherwise get into it, say through a wall cap, which is often the problem with free-standing walls used as partitions.

On the other hand, if the wall is part of an enclosed structure, e.g., the outside wall of the house, then an elastomeric coating can be fine. Keep in mind that you'll be covering the cracks, so moisture will not now be able to escape there, which could have kept the oil-based paint from peeling. If in doubt, use one coat of a flat latex paint, which is the most forgiving type for letting moisture pass through. In any case, first go over the stucco thoroughly with a stiff metal wire brush ( with proper safety precaution) to remove all loose paint and unbound sand. Repair visible cracks with Multiflex AC, then proceed with painting.

Can synthetic stucco (exterior insulated finishes systems, "EIFS") be painted with EWCs to change the color? What type of paint should be used? What surface preparation is needed?

, EIFS is an excellent candidate for painting, in order to change color, refresh the appearance, and to enhance protection. Surface preparation is similar to that with stucco and other masonry surfaces: remove dirt, mildew, any loose sand. Use particular care if power washing, to not force water into joints and any cracks. Power washing should be done with plain water without cleaner or bleach added. Use a quality acrylic (E.g. Multiflex AC) or siliconized caulk to seal any cracks and openings. Leave the caulk to dry over night, and make a second application if necessary. Leave the surface preferably for 48 hours to allow all water from caulk to go out. Apply a masonry primer for best results (sheen uniformity, mildew resistance) e.g. Ultraprime. Then use RainShield EWC a 100% acrylic latex elastomeric wall coating, applied in two heavy coats.

, EIFS is an excellent candidate for painting, in order to change color, refresh the appearance, and to enhance protection. Surface preparation is similar to that with stucco and other masonry surfaces: remove dirt, mildew, any loose sand. Use particular care if power washing, to not force water into joints and any cracks. Power washing should be done with plain water without cleaner or bleach added. Use a quality acrylic (E.g. Multiflex AC) or siliconized caulk to seal any cracks and openings. Leave the caulk to dry over night, and make a second application if necessary. Leave the surface preferably for 48 hours to allow all water from caulk to go out. Apply a masonry primer for best results (sheen uniformity, mildew resistance) e.g. Ultraprime. Then use RainShield EWC a 100% acrylic latex elastomeric wall coating, applied in two heavy coats.

Our building is currently coated with an elastomeric coating and has been for about eight years. It is in good shape functionally but has started to fade and pick up some dirt. We would like to re-paint the buildings without expense of using an elastomeric. What kind of paint and preparation technique do I need to specify to the contractor?

It is always preferable to apply another coat of elastomeric coating, which does not cost much, as the thickness may be much less than what it was applied in the beginning. In fact durability can be further extended to another 5 years with single coat of elastomeric coating, if overall thickness is maintained at 300 microns.

But in case you still prefer to go for paint, then use a quality exterior 100% acrylic latex paint in a flat, satin or semigloss finish. In fact, some paint manufacturers are now recommending their products for this. Here are some guidelines for painting buildings done previously with an elastomeric:

How elastomeric coating is different from house paint?

The use of Elastomeric wall coatings is so pervasive today that it is virtually impossible for relative newcomers in the painting contractor business to imagine how we got along without it. The continual problem of moisture penetration has been so successfully addressed by Elastomerics that it is almost a foregone conclusion for contractors to specify its use in any application where moisture is likely to occur.

Properties |

Textured and Smooth Elastomeric Coatings |

House Paint |

Waterproofs |

|

|

Weatherproofs |

|

|

Saves on year-around energy bills (textured) |

|

|

High-build |

|

|

Flexible |

|

|

Low Maintenance |

|

|

Chip resistant |

|

|

Peel resistant |

|

|

Flake resistant |

|

|

Crack resistant |

|

|

Covers hairline cracks |

|

|

Available in a smooth or textured finish |

|

|

Long term warranty |

|

|